Maintenance of food conveyor belt

Food conveyor belt should be kept in transportation and storage. Avoid sunlight or rain or snow, prevent contact with acid, alkali oil, organic solvents and other substances, and distance from the heating device.In storage, the temperature in the warehouse should be kept between -18 and 40, and the relative temperature should be kept between 50-80%RH. During storage, the product should be placed in volume, not folded, and should be turned every season during the storage.

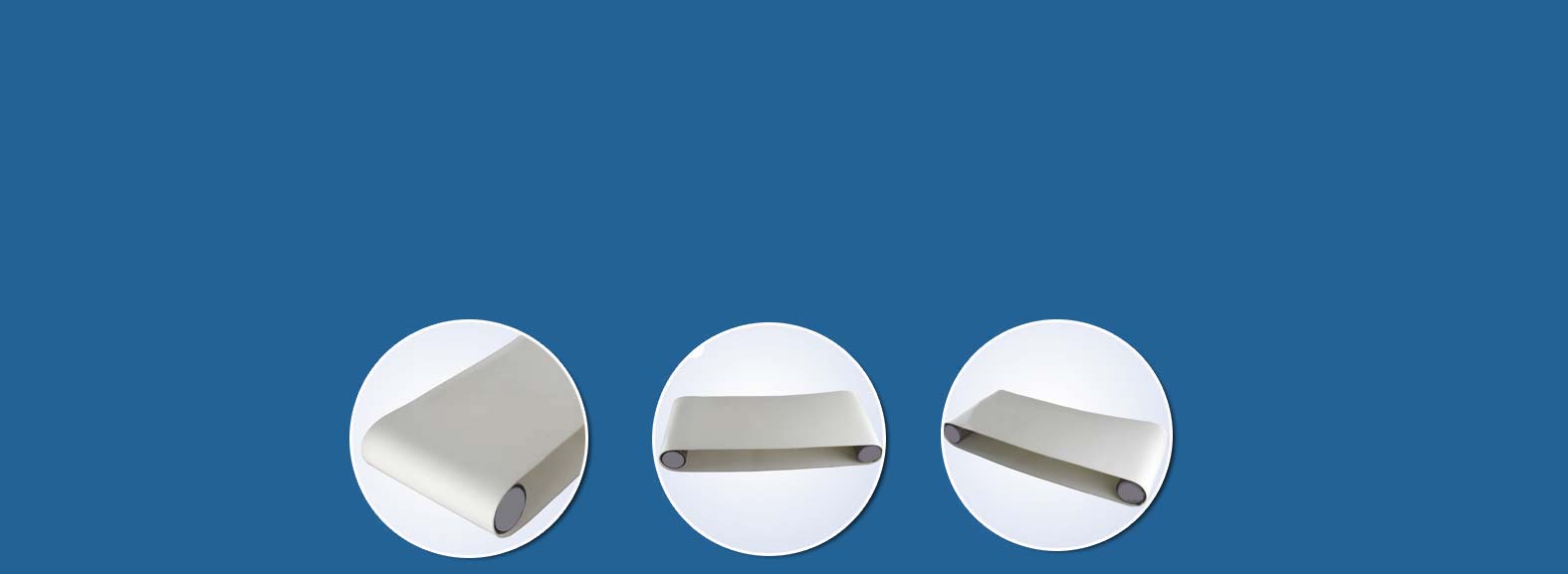

The conveyor belts of different types and specifications are not suitable to be used together, and the joint is better to be glued. The type, structure, specifications and layers of the conveyer belt should be selected according to the conditions of use. The running speed of the conveyer belt should not be as large as 2.5 meters per second, the bulk of the block is large, the material with large wear and the use of the fixed plow type unloading device should be used as far as possible at low speed.

Conveyor drive roller diameter and the conveying belt cloth layer, Guan Di read drum, drum to the supporting roller and groove angle requirements should be based on the design requirements of transport, reasonable selection.

Feeding direction should be running direction of the belt to reduce impact on the tape falling material should be used when the chute, reduce material falling distance; tape feeding section should shorten the distance between rollers and the buffer roller, to prevent leakage, should use the block plate of moderately soft side, in order to avoid blocking plate excellent scratch, conveyor belt surface.