1 Overview

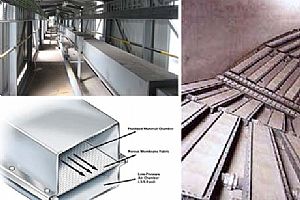

XZ-type air-feeding dike is suitable for transporting cement and other easily fluidized powdery materials, and is not suitable for materials with large particle size, high moisture content and poor fluidization performance.The XZ-type air-feeding dike uses a high-pressure centrifugal blower (9-19) as the power source to keep the material in the closed transport chute fluid flowing slowly towards the slant-down end. XZ-type air-feeding dike main part without transmission parts, convenient sealing operation management, easy starting, parking, low noise, no need of lubrication, almost no maintenance, light weight equipment, low power consumption, large conveying capacity, easy to change conveying Direction, using the new polyester Air Slide Fabric and other advantages.The XZ-type Air slide conveyor systems consists of upper and lower troughs, with a special air slide fabric as the air-permeable layer to separate upper and lower troughs.The Air Slide Fabric doubles the lifespan of the older chute Air Slide Fabric. When the high-pressure air enters the lower tank and enters through the Air Slide Fabric, the upper tank is in a fluid state and flows under gravity to achieve the purpose of transportation.

2. The technical performance list is as follows:

Project | Type | ||||||

200 | 250 | 315 | 400 | 500 | |||

Groove width | 200 | 250 | 315 | 400 | 500 | ||

Production the amount t/h | 8° | cement | 22 | 40 | 70 | 130 | 220 |

Raw material | 16 | 30 | 55 | 100 | 165 | ||

10°cement | 40 | 65 | 120 | 250 | 400 | ||

Raw material | 30 | 55 | 90 | 185 | 300 | ||

Wind pressureKPa | 2--3 | ||||||

Air volume m3/m2.min | 1.5--2 | ||||||

3, installation:

1, the general straight line conveyor installation and inward and downward material tilted 6--10 degrees, the upper and lower tank body and the groove connecting point to achieve a reliable and reliable seal (can add pad);2, need to turn with a 90-degree bend (about minutes);3, need to use a three-way trough or four-way trough and after the delivery of the valve is loaded. In order to control the flow of the fluidized material, ensure that the material is "inflated" for wind, and the deactivated section can reduce the amount of wind consumption;4. After the conveying line is too long or after the delivery, add the fan on the side of the lower tank;

The Air slide conveyor systems gas consumption formula is as follows:V=60×α×(B/1000)×LIn the formula V - gas consumption m3/hThe gas consumption of α - per unit area gas permeable layer is generally 2.0 - 3m3/m2 min;B—the width of the chute;L—chute length m.

5, XZ-type air transport inclined exhaust air in the trough on the discharge tank exhaust, after the exhaust pipe should be entered into a small cloth bag dust mouth, the air volume is 1.5 times the amount of air required, the trough at the outlet pressure requirements Stay around 0.

4, use and maintenance:

1. When XZ-type air is conveyed in a mess, first open the fan and feed again. When the machine shuts down, stop feeding first, wait for the material to finish (or close to sending), and then stop the fan. The fan on the tiller will stop when not in use;2, the trough should be kept sealed, if leakage, leakage powder should be overhauled;3. When installing or replacing Polyester Air Slide Fabric:

a. Trim, cut the Air Slide Fabric to the required size, and block the incision with an electric iron (or a heated steel bar) to prevent it from dissipating;b. Make a hole, heat it with an iron bar that is slightly smaller than the diameter of the mounting bolt, and pierce the area around the Air Slide Fabric that needs to be perforated. Be careful not to let the open flame burn the Air Slide Fabric when punching. If drilling with a drilling rig, use a hot iron stick to block the hole during the hole to prevent it from dissipating.c. Spread the Air Slide Fabric on the flush box, pass through the bolts, tighten the iron bars around it, and tighten the screw to use.d. The burrs (or flanges) should be deburred and the joints ground.e. To ensure the seal, apply a polymer sealant (or felt pad) on the Air Slide Fabric around the lower surface.

5.Air Slide Fabric Technical Specifications

Items | index | |

Temperature resistance | Always≤ | 150℃ |

Instantaneous≤ | 180℃ | |

Breaking strength | Radial≥ | 4700N/mm |

Zonal≥ | 3500N/mm | |

Breaking strength... | In 2m³/m²min | 800Pa-1200Pa |

In<3m³/m²min | <2000Pa | |

6. Air Slide Fabric Transportation and Storage

The Air Slide Fabric should be handled gently during transportation, and it must not be handled arbitrarily.The transportation tools should be clean, and must not be mixed and transported with oils and chemicals. At the same time, there should be measures to prevent sun exposure, rain, and snow showers.The Air Slide Fabric should be stored in a dry, well ventilated warehouse.It must not be mixed with oil chemicals. It should be protected against moisture and kept away from heat sources.

7. Startup and parking considerations

When the machine is turned on, the fan is turned on and then the material hopper gate is opened, and then the total sluice gate is opened. After closing, the total sluice gate is closed to stop feeding.After the material is sent, the fan is stopped and the sluice gate is closed.The lower end of the fan and the channel on the ram The fan stops when not in use